Hydraulic systems are the backbone of modern industry, driving equipment that requires accurate, high power and reliable performance. Hydraulic systems allow industries to handle heavy loads, handle accurate movements and operate effectively under the conditions of demand by transferring energy through pressure fluids.

From construction machinery to aviation control, hydrolics are important for applications where mechanical or pneumatic systems cannot meet essential force, accuracy or safety standards. While standard industrial hydraulic systems address general requirements, customized hydraulic solutions allow specific operations, environmental or government requirements for analog designs.

Understand industrially hydraulic system

Industrial hydraulic systems rely on fluid strength transfer, converting fluid pressure at mechanical speed or power. The efficiency and reliability of these systems make them an important component of many industrial applications.

Applications include:

Building machines: taps, bulldozers, excavators and loads for strong lift and accurate movement.

Production equipment: Hydraulic press, casting machine and automated mounting lines for high volume production.

Agricultural machinery: Tractors, autumn and irrigation systems that require frequent performance in the external environment.

Marine and offshore equipment: control systems, stabilizers and winners designed to meet saltwater roast and extreme conditions.

Aviation and defense: Landing equipment, flight control actors and crushing systems seeking accurate and reliable operations.

Industrial hydrolics are preferred for their high strength-to-war conditions, accurate control and durability in continuous or heavy operations.

Why customized hydraulic systems are important

Standard systems serve general targets, but custom hydraulic systems provide unique benefits for special operations:

Extreme operating conditions: Offshore rigs, desert environment, high altitude locations and dangerous places.

Special load management: High pressure cycle, repetition rate or unique load requirements.

Automation integration: Robotics basically work with CNC machines and smart control systems.

Compliance with industry standards: ISO 4413, SAE and sector -specific certificates ensure safe, reliable and regulated operations.

Energy efficiency and stability: Analog design reduces energy consumption and the tools maximize life.

Custom solutions are important for industries that require precise, reliability and adaptability in a challenging environment.

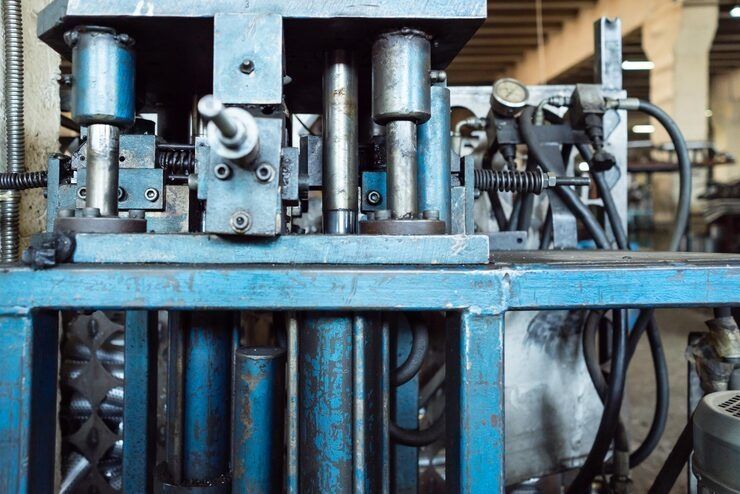

Main components in hydraulic systems

Intensive understanding of the main components is required for proper design, operation and maintenance:

Hydraulic pump: fluid flows and pressure. The types include equipment, stamp and vein pumps.

Reservoirs: Store the liquid while keeping the contaminants out and dissolving the heat.

Valve: Control current, pressure and direction. Czech, relief and proportional valves are included.

Actuators: Convert fluid to mechanical movement; Hydraulic cylinders and engines are included.

Hoses and pipes: Transport fluid under high pressure with minimal leakage.

Filter: Protect sensitive components from contaminants.

Sensors and controls: Enable monitoring, automation and integration with digital systems.

Custom hydraulic systems may include advanced modules, smart sensors and energy -saving players to meet special requirements.

Newer updates and trends (2024–2025)

Hydraulic era is developing unexpectedly to fulfill enterprise requirements for performance, balance and virtual integration:

Smart Hydrolika and IoT: The sensor presents actual -time facts for destiny preservation, which reduces downtime.

Energy-capable layout: Variabotions pumps, hybrid electro-hydrolics and energy recuperation device reduce power use.

Environmentally friendly fluids: Biodegradable hydraulic oils reduce environmental outcomes and observe strict stability laws.

Compact, modular device: Mobile machinery, city manufacturing and area-saving answers for offshore platforms.

Automation and AI integration: Accurate control via robot interfaces, AI-assisted feedback and digital optimization.

3D-touched additives: Some manufacturers now use additive manufacturing for moderate, custom fashioned parts.

These tendencies emphasize a alternate to shrewd, long lasting and rather adaptable hydraulic answers in contemporary industry.

Compliance, rules and tips

Hydraulic systems are situation to protection, environmental and pleasant rules to make sure operational reliability:

Safety requirements: Proper set up, inspection and operator training are required to prevent injuries.

Environmental compliance: Fluid management, leakage prevention, waste control and environmentally friendly fluid.

Industry requirements: ISO 4413, SAE and ANSI make certain preferred design, working performance and compatibility.

Certification requirements: Aviation, protection and offshore industries regularly make licensed hydraulic systems compulsory.

Direction to replica: Some regions provide regulated access to scientific device for unbiased maintenance and controlled to devise.

According to the regulations, felony compliance, secure operation and the lifestyles of the gadget ensure life.

The benefits of industrial and custom hydraulic systems

High strength-to-war conditions for heavy applications.

Accurate speed control for automated or repetitive features.

Reliability in extreme environmental conditions.

Long life with proper maintenance.

Energy-capable design reduces operating expenses and environmental impact.

Flexible adaptation for future expansion or development of industrial requirements.

Custom hydraulic systems allow companies to maximize productivity by reducing operating risk.

Maintenance fine conduct

Maintaining hydraulic systems is crucial for protection, efficiency and lifetime:

Observe hoses, seals and fittings for placed on and leakage.

Perform ordinary hydraulic fluid evaluation to display infection or fall.

Change the filter out consistent with the producer's tips.

Caliber sensor and controller regularly.

Use preventive upkeep packages relying on hours of use and walking conditions.

Future theft and preventive maintenance practices lessen unplanned closures and growth the general performance of the overall device.

Tools and resources

Professional hydraulic systems can use different types of equipment for optimization:

Hydraulic design and simulation software: CAD and special modeling equipment.

Liquid analysis set: To monitor the oil position and prevent pollution.

Censorship Platform and Monitoring System: Future Focus and Real Time Diagnosis.

Industry document: ISO, SAE and ANSI standard for compliance and best practice.

Training program: Course in hydraulic troubleshooting, advanced design and safe operation.

Using these devices ensures effective, secure and durable hydraulic system operations.

Frequently requested questions

Q1. Which industries are most counting on hydraulic structures?

Construction, manufacturing, agriculture, aerospace, marine and renewable energy regions use huge hydraulic structures.

Q2. Why are custom hydraulic systems vital?

They remedy special operational traumatic situations, beautify typical performance, increase safety and increase the life of the device.

Q3. How long can a hydraulic tool final?

With proper maintenance, business and custom hydraulic systems can closing for 15-two decades or more.

Q4. Are hydraulic structures environmentally superb?

Yes, current-day structures use biodegradable liquids, energy -green designs and leakage prevention measures.

Q5. Give form to hydraulic systems in 2025?

Smart Hydrolika, IoT integration, hybrid systems, modular designs, AI-assisted control and environmentally super fluids are great tendencies.

conclusion

Industrial and adapted hydraulic structures are still important to the current industry, providing strength, accuracy and adaptability. While popular structures meet general requirements, customized solutions are significant general performance, strong and efficiency for specialized industrial applications.

To learn machine components, keep up to date on technical symptoms, and follow according to conformity requirements, engineers and selection creators can maximize operating efficiency, safety and stability. With the right setup, integration and maintenance, hydraulic structures are 2025 and lately the entire industry in industries puts pressure on innovation and productivity.